THE ESTABLISHMENT

The Establishment Graphic Franco is characterized by integrating in its plant, all stages of the productive process by combining the expertise and professionalism of more than 40 years of experience in the printing market.

Areas

-

DESIGN & PRE-PRESS / RESOLUTION IN THE CREATION OF NEW PRODUCTS

Open or CloseThis department is equipped to comprehensively fulfill the design and pre-press process. It begins with the development of cutting marks, preparation of the sample with the material to be used, and digital color graphic design until obtaining the printing plates through CTP (computer to plate) with on line developing process.

All these processes are supported by modern pre-press software used on Mac and Pc platforms, which provide solutions to all the needs that may arise during the creation of a new product.

-

PRINTING AREA / HIGH PERFORMANCE TECHNOLOGY

Open or CloseThis department has 18 high performance printing machines, remote adjustment of registers, and remote dying control, on line varnishing and tempering of the printing machines, in order to assure the best quality of the printing material.

Technological Incorporation

We have recently added a modern 6-position MAN Roland 706 TLV, which is a 12-part system, synchronized from a control console, and it is used to optimize uptime as well as reducing costs.

We have installed an Automatic Printing Control system which ensures a consistent printing by means of Quality Protocols.

-

AUTOMATIC CASE / GLUER

-

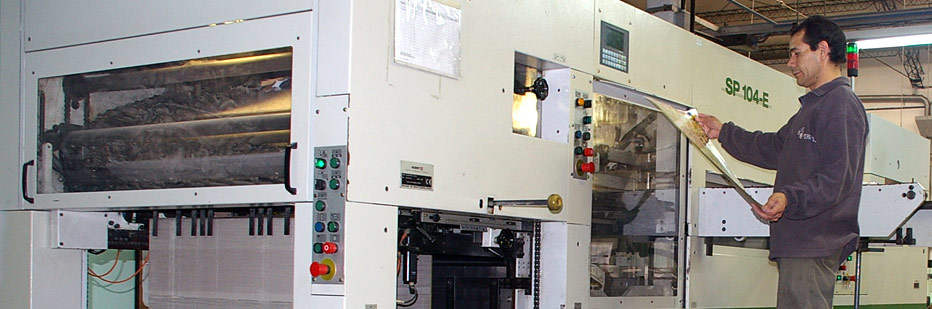

HIGH SPEED, AUTOMATIC DIE CUTTERS AREA

This sector is composed of four die cut machines, equipped to effectively solve the demands of the different production volumes; automatic unpacking is used to speed up the processes involved, keeping in mind, at every moment, our goal of obtaining better products.

-

WAREHOUSE & LOGISTICS / PERMANENT STOCK

In order to manufacture our products we have a permanent stock of card stock (having different origins, and several weights and shapes) enabling us to offer a wide coverage to our client's needs. Warehousing is currently over 500 tons; thus, being able to quickly face any challenge regardless of the volume.

Logistics Department

This department is in charge of the evaluation and follow-up of each project, being ahead of future processes and delivery deadlines. Assuring, in this way, that the agreed deadlines are met and notifying our clients.

-

MANUFACTURING / MICRO-CORRUGATED PACKAGING

Using micro-corrugated material in the manufacturing packaging is a complement of the company used to meet the needs of the clients who coming from different industrial activities, are forced to use resistant containers, which at the same time do not affect the aesthetic external appearance of their products.

After several years of developing this area, we have obtained an efficient continuous production structure and a constant stock to face big volume projects demanded by the market.