PRODUCT DEVELOPMENT

-

Our main objective is to create packages selling!

From concept to consumer.

Ideas become realities, with innovation and design, combining functionality and creativity to constantly surprise and satisfy consumers.

Great variety of dies and a professional team will assist you to make your case meets the functions contain, protect and store the final product.

Our machines are suitable to print various substrates from cardboard, microcorrugated, double triple, waves B, E and an innovative wave N, cardboard, kraft paper and liners, we are pioneers in the market.

We use top finishes, as shiny, lacquer sectored hardware (hotstamping gold / silver), polypropylene, polyethylene, PVC windows, and a very good picture quality to sell, attract and generate a positive reaction in the Consumer.

-

Kind of package

These are some examples of products

-

MATERIALS

CORRUGATED PACKAGING BASICS

-

CORRUGATED

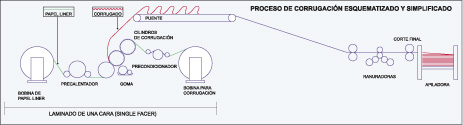

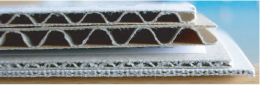

Open or CloseCorrugated cardboard is a combination of what is known as a liner and flute, wherein the liner is a thick flat sheet and pipe, a corrugated sheet that is adhered to the liner by means of rubber pressure and heat. All this, based fact pine pulp or recycled paper.

Corrugated cardboard, unable to obtain additional strength through the double boxes, unions and special perforations are given to those in key parts of their structural designs, which are designed based on the specific use to which they will go.

click on the images

to zoomKIND OF CORRUGATED

Single Face: It's a linerboard sheet corrugated sheet attached to another, is mainly used to wrap objects.

-

CORRUGATED CARTON SIZES

Open or CloseThe number and size of arcs per meter containing corrugated cardboard sheets, determine their size and their functionality. Currently manufacture three different wave types (B, E, N).

Wave B, mainly used in the automotive industry and toy industry, has greater rigidity for heavy products.

Wave E, used in the food, toy and pharmaceutical, have less stiffness and good surface finish, giving priority to aesthetics.

Wave N, used in the technology industry, has greater stiffness than cardboard, with a similar surface finish.

-

CARDBOARD

Open or CloseThe number and size of arcs per meter sheets containing Cardboard is the product obtained from the treatment of one or more layers of bleached or unbleached cellulose, these layers provide different thicknesses and stiffnesses.

The cardboard can make using recycled or virgin fibers. Are usually stuccoed, which process provides whiteness, softness and the ability to be printed and can be stuck on one side or on both sides.

Duplex cardboard:

Made from raw or recycled pulp, bleached, which gives it its characteristic brown color on the back, and plastered on one side.

Triplex cardboard:

Made with bleached, which gives its particular target on the back, and plastered on one side.

CARDBOARDS SPECIFICATIONS:

Papelera del Sur Klavin CMPC Duplex/Triplex Duplex Duplex/Triplex Recycled components Built with pine fiber Built with pine fiber Medium Rigidity High Rigidity and grammage High Rigidity and grammage Made in: Argentina Made in: Brasil Made in: Chile • Papelera del Sur (PDF) • Klafold (PDF in Inglés)

• Klafold (PDF in Portugues)• GC1 - White (PDF)

• RC - Marrón (PDF)

-

-

Development Requirements

For proper implementation of the Packaging Development and Product Prepress, Graphic Establishment Franco suggests certain standard rules and requirements when you submit the job information to make in order to comply in a timely manner in the delivery of the final product.

-

In Product Development (punch-case):

Open or Close- Previous printed similar series or reference.

- Objectives to be met by the packaging (if required a totally new design should follow a guideline or above).

- MCorrect measures or similar flat, cd-dvd provided with graphic design.

- Material specifications (wave direction, thickness).

- Using packaging and logistics (whether for domestic market, whether to export and in what medium, etc..).

- Sample or example domestic product containing the packaging.

- If samples are required armed packaging, ask for them ahead and approve them as soon as possible to continue the production and prepress punch.

-

In the Original Prepress:

Open or Close- CD-DVD copy prepress files (a copy and not returned to the client, since the original so will the client). Establecimiento Gráfico Franco responsible for the use of the information, in turn ensures strict client confidentiality.

- For FTP or email to: preprensa@egfranco.com.ar: archives and compression extension.

- Originals typeface and in curves.

- Folder with specific font family used in the document, that can be installed.

- Pictures linked in photo formats: “.psd”, “.tif”, “.eps”, “.dcs”, “.jpg”, and not embedded in the document, so that they are editable.

- 300 dpi resolution at least in pictures.

- Photographs applied to 100% (to 120% tolerance magnification).

- Pictures in layers (layers).

- Pictures without text or logos, they must be vectors (illustrator).

- Photos with CMYK color mode or GRAYSCALE.

- In contain colors in the photograph, indicate with a note or printed, or specified in the Illustrator file.

- Vector file formats: AI, Coreldraw exported, EPS, PDF, ART.

- Specification or foot-designer with many colors where you want the final separation of the packaging.

- Printed previous similar series or reference.

- Samples of special colors and / or photographs to match.

- Original file Printing actual size (100%) with ok client / advertising agency.

- Change Orders by e-mail text or indicated in the original print.

- Specify if you require high quality Digital Test for final approval.

- Final approval prepress stage by e-mail in a timely manner to continue production.

-